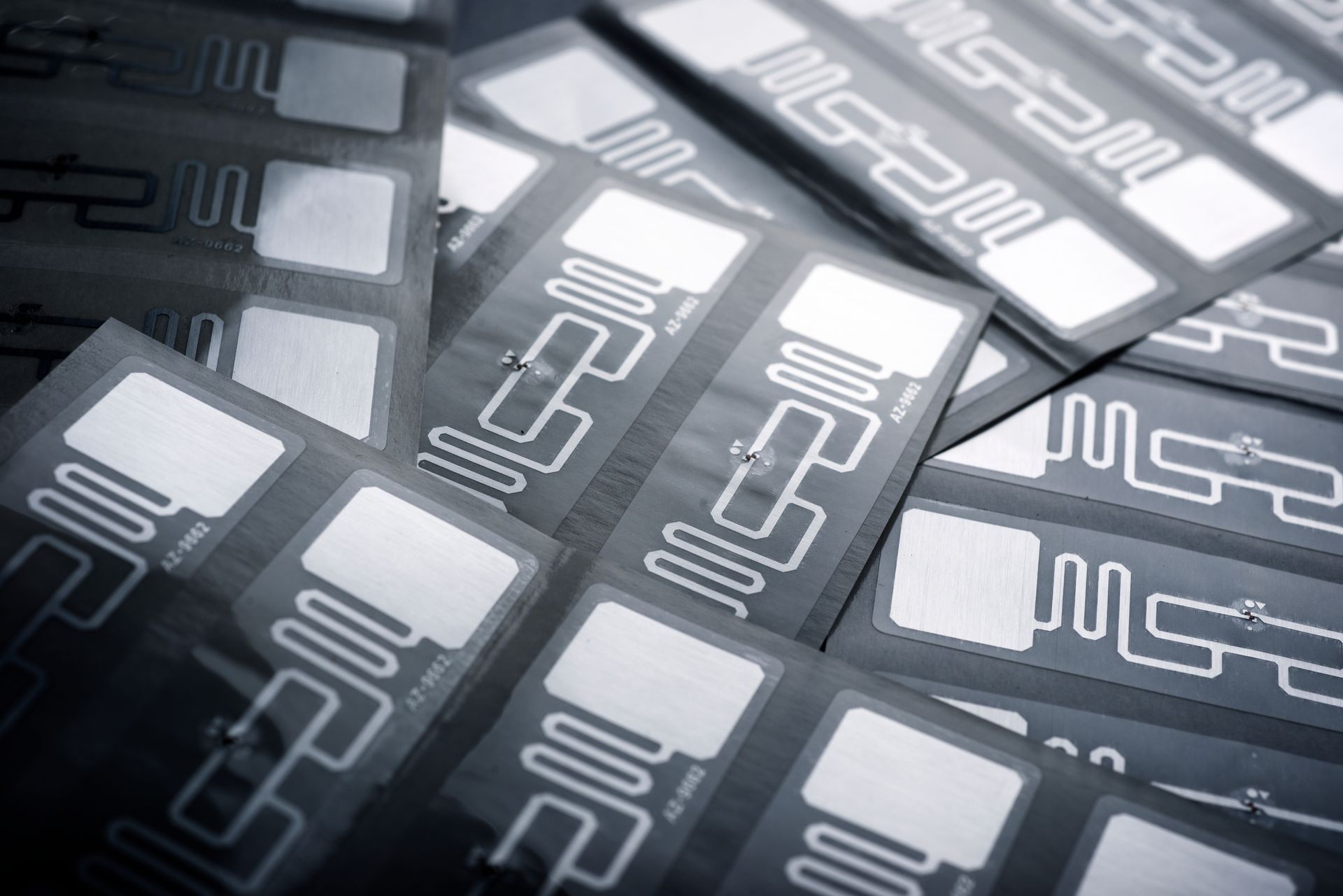

Radio Frequency Identification Labels

Our unique printing and adhesive capabilities. We "Produce" RFID labels and have the ability to "Insert" RFID directly into existing labels

Saxon produces high-quality RFID inlay labels designed for precision, performance, and reliability

Radio Frequency Identification Labels

Our unique printing and adhesive capabilities. We "Produce" RFID labels and have the ability to "Insert" RFID directly into existing labels

Saxon produces high-quality RFID inlay labels designed for precision, performance, and reliability

RFID

Key benefits of producing a label with an RFID chip inside

Already have an existing label? No problem, we have the unique ability to insert on existing labels.

NFC (Near Field Communication) Labels - we print NFC labels that help you deliver powerful value by bridging the physical and digital worlds with a simple tap. NFC enhances customer engagement, streamlines workflows, and adds a layer of security and traceability that standard labels cannot provide.

Fast, hands-free inventory counts, read many items at once without line-of-sight scanning (vs barcodes). Huge time savings for stock takes and receiving.

- Longer read range (when needed) UHF passive tags can be read several meters away, enabling conveyor/portal reading and automated gates.

- Bulk and simultaneous reading dozens to hundreds of tagged items can be read in one pass, increasing throughput.

- Better supply-chain visibility track items through warehouse, transit, retail, returns, status and location updates become easier and more accurate.

- Tamper evidence & anti-counterfeit tamper-resistant labels and serialized RFID chips help prove authenticity.

- More data on the tag store a serial, product data or small state info on the chip (not unlimited, but more flexible than a printed barcode).

- Durability properly embedded inlays survive rough handling, moisture, chemicals and outdoor exposure (better than printed labels alone).

- Automation/enabled workflows auto-replenishment, automated checkout, loss prevention, workflow triggers when tagged goods enter/leave zones.

- Fewer human errors automated reads reduce manual scanning mistakes (mis-scans, missed items).

- Integration with analytics real-time movement data feeds BI systems for lead-time, shrinkage, picking efficiency analysis.

- Specialized sensing some advanced tags can include sensors (temperature, shock), useful for cold chain or fragile goods.

Integrator or Direct

We Provide Timely - High Quality Solutions

Every Time!